Optimized forGoogle Chrome version.

BLUEWIN Co., Ltd.

a Family Group, Manufactuere & EPC company for

-

Leading the Future of Sludge Dewatering, Drying & Resource Recovery

-

High-Efficiency Water, Wastewater & Algae Treatment Excellence

-

A Century-Ahead Top-Down Natural Nano Technology Innovation

38 years Accumulated know how,

Move the World by Green Advanced Technology

World 1st, World Unique

Sludge Dewatering, Reduction, Drying

by ELODE & NVD

ELODE+NVD - The best solution for Sludge Dewatering, Drying

ELODE CORE TECHNOLOGY & ACTUAL OPERATING-MOVIE

For more details : www.bluewin.co.kr

-------------------------------------------------------------------------------------------- 📢EXHIBITION NOTICE📢

📢 Join BLUEWIN-MIVALT s.r.o. Joint Show

at [AQUATECH2025-Amsterdam, The Netherelands]!

🌍 AQUATECH 2025: https://www.aquatechtrade.com

📅 March/11~14/2025

📍 Booth No: 03-413

📢 Join BLUEWIN Show

at [WATERKOREA 2025-SEOUL KINTEX KOREA]!

🌍 WATERKOREA 2025: https://www.waterkorea.kr

📅 March/19~21/2025

📍 Booth No: D38

Discover our cutting-edge ELODE / NVD dewatering system in action!

BLUEWIN is leading innovation in the global environmental industry.

Visit our booth and let’s discuss the future together! 😊

👉 Contact us: Email: bluewin@bluewin.kr or antonio.kim@elode.co

Key Technology

Superior quality of wastewater sludge dehydrator

ELODE (Electro Osmosis Dehydrator) for remarkable sludge dewatering and remake renewable energy for all kinds of WWTP, WTP sludge.

AN AWARD-WINNING (Excellent Machine certificate) superior quality of wastewater sludge dehydrator ELODE, the world's first field-proven commercialized electro-osmosis dehydrator which treats all types of wastewater including municipal sewage, paper-mill wastewater, food wastewater, livestock wastewater, wastewater from dyeing, wastewater from painting, chemical wastewater, pit wastewater, etc.

ELODE extracts both free and absorbed water from the sludge producing a final dehydrated product with a moisture content of 10% (i.e. 90% dry solids content). This ensures maximum dehydration performance with minimum environmental impact. ELODE can be installed as a complete system or in addition to an existing sludge treatment system.

ELODE can be installed as a complete system or in addition to an existing sludge treatment system. With more than 25 years of dedication, we are constantly applying the latest technology in equipment design to continuously improve our environment. This focus helps us design and manufacture the most efficient and best performing equipment. We aim to combine tradition, innovation and quality to provide the optimum equipment which will exceed our customer's expectations.

Hope you to apply this ELODE system for your current "sludge reduction project" or introduce to your business client to cut down a lot of cost and fast Recovery of initial Investment. Hope you have great business choice. ELODE should be a high valuable profit for your new business.

Methods of Dehydration by ELODE

ELODE is based upon a technology allowing highly efficient dehydration to take place by extracting “free water” and “absorbed water” from sludge using electrophoresis and electro-osmosis. It is distinguished from conventional dehydration methods which only extract the free water from liquid sludge by applying high pressure and consuming large amounts of coagulation and flocculation polymers.

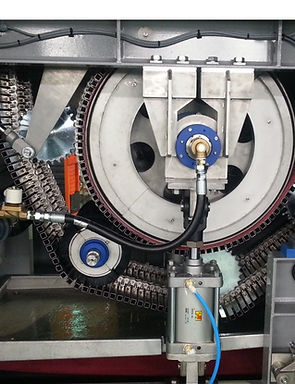

Dewatered sludge cake is fed between the anode drum and cathode caterpillar of the ELODE machine. A three phase alternating current (AC), converted to direct current (DC) is applied to the anode drum and cathode caterpillar creating an electrical potential difference. This leads to a strong migration of sludge particles to the anode drum and water to cathode caterpillar. Thus, highly efficient dehydration with a water content below 40~60wt% is achieved.

Supply Model

Single ELODE is a compact second stage dehydrator using Electro-Osmosis to further dehydrate sludge cake from conventional dewatering equipment. This produces a drier sludge and significant reductions in sludge weight. It can be easily be integrated into any conventional dewatering system such as belt-press, filter press, decanter (centrifuge), gravity dehydration etc. The sludge must be thickened to 95wt% moisture content or less by conventional means before it can be treated by Single ELODE.

Bult-in ELODE, a highly efficient dehydrator that combines first stage mechanical dewatering by Belt-Press with second stage Electro-Osmosis. This is a highly effective process which reduces the final sludge cake dryness to or below 10wt% moisture content (a dehydration ratio of over 90%). This means the volume of the sludge is reduced to less than 10% of the input sludge and 50% less than conventional dewatering equipment. Built-in ELODE is a compact and robust machine, where low noise, ease of operation, flexibility and low maintenance are critical.

What has been Up-Graded?

Long life span!

Low operating cost!

Faster ROI!

New technology applied to Core parts!

The main component of the electro-osmosis dehydrator is “Main Drum”.

In case of existing ELODE's equipment, when the conductivity of the sludge is above 6000㎲, the electricity consumption suddenly is increased by the sudden current application from the sludge. at same time, such this kinds of problem is making the explosion, the melting of the belt filter occurred due to the spark phenomenon and gas generation.

Up-graded New ELODE is completely solved this kinds of problem. NEW ELODE has not only a very high efficiency dewatering rate even 15,000㎲ but also has reduced electric energy consumption more than 20% compared to conventional ELODE.

In case of NEW ELODE-3000 (Belt Width 3000mm) Main Drum guarantees 24 months at high-conductivity sludge of 15000㎲, and replacement cost is cheaper than conventional ELODE..

NEW ELODE with breakdown free.

After the final commercialization in 2016, 2 sets ELODE, as ELODE-15 (Belt Width 1500mm) and ELODE-30 (Belt Width 3000mm) were installed in SongWon Industries and Dupont® Korea for each, which were the most difficult organic dewatered sludge with 15,000μs conductivity. It has been completely operating & up-graded for 3 years without any troubles.

Especially 20% electric consumption was saved (Max. 280kW down to 220kW at 3000mm Belt-width), reduced 50% final cake volume, ROI was less 2years. The most expendable Beltfilter is developed as a special Beltfilter that guarantees low price and long durability, Caterpillar does not need to be replaced, and the Main Drum has enhanced durability to withstand the worst sludge.

See the NEW UP-GRADED ELODE now!!.